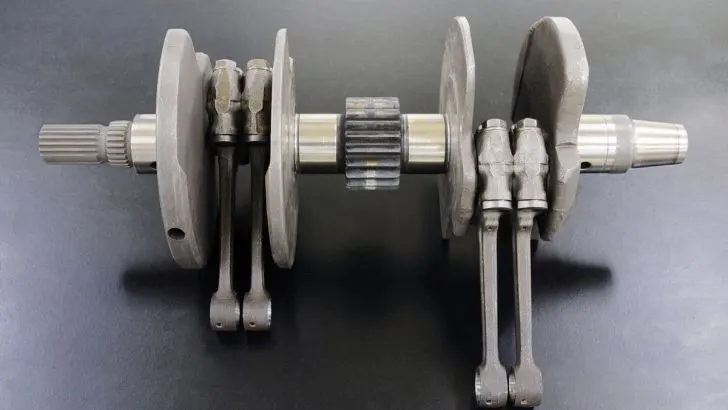

Kawasaki Teryx vehicles are high-quality recreational side-by-sides, and Kawasaki has been improving on their original model since 2008. However, even top-quality vehicles have problems sometimes, and the Teryx is no exception. One issue you might encounter is a problem with the crankshaft.

Fixing a damaged Kawasaki Teryx crankshaft is a complicated mechanical process that involves locating and removing the crankshaft. You should then grind, straighten it, weld any cracks, replace the bearings, and nitride it for durability.

In this article, I’ll explain each step of fixing a damaged Kawasaki Teryx crankshaft. Keep reading if you have mechanical experience and feel confident in your DIY ability!

1. Locate and Remove the Crankshaft

The first part of fixing crankshaft damage is reaching the crankshaft itself. The crankshaft is located underneath the engine cover, and removing it isn’t too difficult. You will need to remove the crank bolt or nut by turning it counterclockwise with a wrench. Then, remove any washers inside the crank (source).

I like using a wrench from my Craftsman Wrench Set (link to Amazon). I like this set because the full polish chrome finish on the wrenches is corrosion-resistant, so the tools will last a long time. The wrenches come with a 15-degree box end offset, so there’s additional knuckle clearance. Finally, I appreciate that the wrenches have large markings that identify their size, so I can quickly find the one I need.

Once you’ve removed the crankshaft from the vehicle, it’s time to inspect it. Sometimes, it is so damaged that a complete replacement is necessary. Crankshafts get worn down relatively quickly due to mechanical overload, lubricating oil deficiency, or incorrect bearing clearances. Because of their vulnerability, they may need replacement more frequently than other vehicle parts (source).

If you think your crankshaft is repairable, you can continue to the next steps.

2. Grind the Surface

Grinding is an essential part of crankshaft repair. Over time, the fit between the crankshaft and the bearings changes and becomes misaligned, and grinding a crankshaft will reduce the stress of this misalignment (source).

You’ll need to grind the top layer of the crankshaft to remove the worn-out surface and eliminate any scratches, corrosion, foreign materials, and contaminants. This step requires a crankshaft grinding machine, and unless you have one lying around at home, you’ll need to get a professional’s help. The standard amount of surface removed in the grinding process is 0.005 inches (0.01 cm).

3. Weld Any Cracks

If there are any cracks, tears, or splits on the crankshaft surface, they will need to be welded together. This step involves using a thermal spray and a welding and straightening machine, so you’ll likely need to take your vehicle to a professional and experienced welder. Some areas on a crankshaft are difficult to reach with a welding torch.

4. Straighten the Crankshaft

After grinding and welding, the crankshaft may not be straight or aligned anymore. The radius and the dimensions need to be spot-on for the crankshaft to work properly and for your Kawasaki Teryx to run the way you want it to.

You’ll need to place the crankshaft in a hydraulic press, which has indicators that determine the length of the various parts of the crankshaft. Once you have the measurements, you should consult your Kawasaki Teryx user manual to find the original specs.

Once you have this, apply pressure to the crankshaft to bend it into place, according to the original equipment manufacturer.

This BIG RED T51201 Torin Steel H-Frame Hydraulic Floor Press (link to Amazon) is a heavy-duty, high-quality machine designed for straightening, bending, pressing, and stamping. A major benefit of this product is that you can raise and lower the table to get the right distance for individual jobs, and the precision springs are high-quality and safely bounce back after pressing.

5. Replace the Bearings

Sometimes, you’ll need to replace the crankshaft bearings because they are too worn down to continue working properly. Use a clean, lint-free cloth to remove the new bearings before installing them. The bearings take the brunt of the stress in the crankshaft setup, so I recommend replacing them if you’ve already gone through all the other steps mentioned above.

This Sealed Power 4663MA Main Bearing Set (link to Amazon) is compatible with Kawasaki Teryx crankshafts and has greater seizure resistance than tri-metal material. These bearings’ high-quality material and construction reduce wear dramatically and exceed original equipment manufacturer specifications.

6. Clean the Crankshaft

The crankshaft needs oil to move easily through its channels and passageways to prevent wear and tear due to insufficient lubrication, so I recommend taking the time to clean these channels and ensure that there aren’t any blockages or debris getting in the way of its path. For cleaning, I recommend using a lint-free microfiber cloth.

7. Nitride the Crankshaft

Nitriding is a process that hardens the surface of a metal component, which can reduce wear over time. I recommend nitriding your crankshaft once you’re done with all the repairs to increase the durability and longevity of your crankshaft (source).

Using this surface hardening technology greatly reduces bending fatigue and the wear properties of the steel components of your crankshaft. The process usually hardens the crank to a depth of 0.20 to 0.30 inches (0.51 to 0.76 cm). Traditionally, nitriding was only used for military vehicles and commercial aircraft, but nowadays, you can find people who perform the service for recreational vehicles.

If these repairs don’t work, or if your crankshaft is so damaged that it is past the point of repair, you may need to complete an engine rebuild. You can purchase engine rebuild kits online at various mechanics’ websites.

This Wrench Rabbit Complete Engine Rebuild Kit (link to Amazon) is compatible with the Kawasaki 750 Teryx and is a 100% brand-new aftermarket unit with high-quality parts, including everything you’ll need to replace the crankshaft. The parts all meet or exceed the original equipment manufacturer’s fit and performance specifications. I also like that Wrench Rabbit is a USA-based company.

If you ride a Kawasaki Teryx, you may hear strange noises from the engine. What’s the reason, and how do you fix it? Click on the link to learn more.

Final Thoughts

Fixing a damaged Kawasaki Teryx crankshaft is a difficult mechanical process requiring great DIY skills and mechanical know-how. To fix a crankshaft, you must first locate and remove it. Following an inspection, you’ll need to grind it and weld any cracks. Then, you need to straighten it and replace the bearings. A clean and nitride-treated crankshaft is more durable and will last longer.